Customer Spotlight – Adventist Healthcare Shady Grove Medical Center

When Greg Hebron started as Director of Environmental Services (EVS) at Adventist HealthCare Shady Grove Medical Center in February 2023, the hospital needed to lower its linen loss costs. Greg used his past experiences in banking, sales and EVS management and his previous partnership with HandCraft Linen Services to work with his team and formulate a successful linen management strategy.

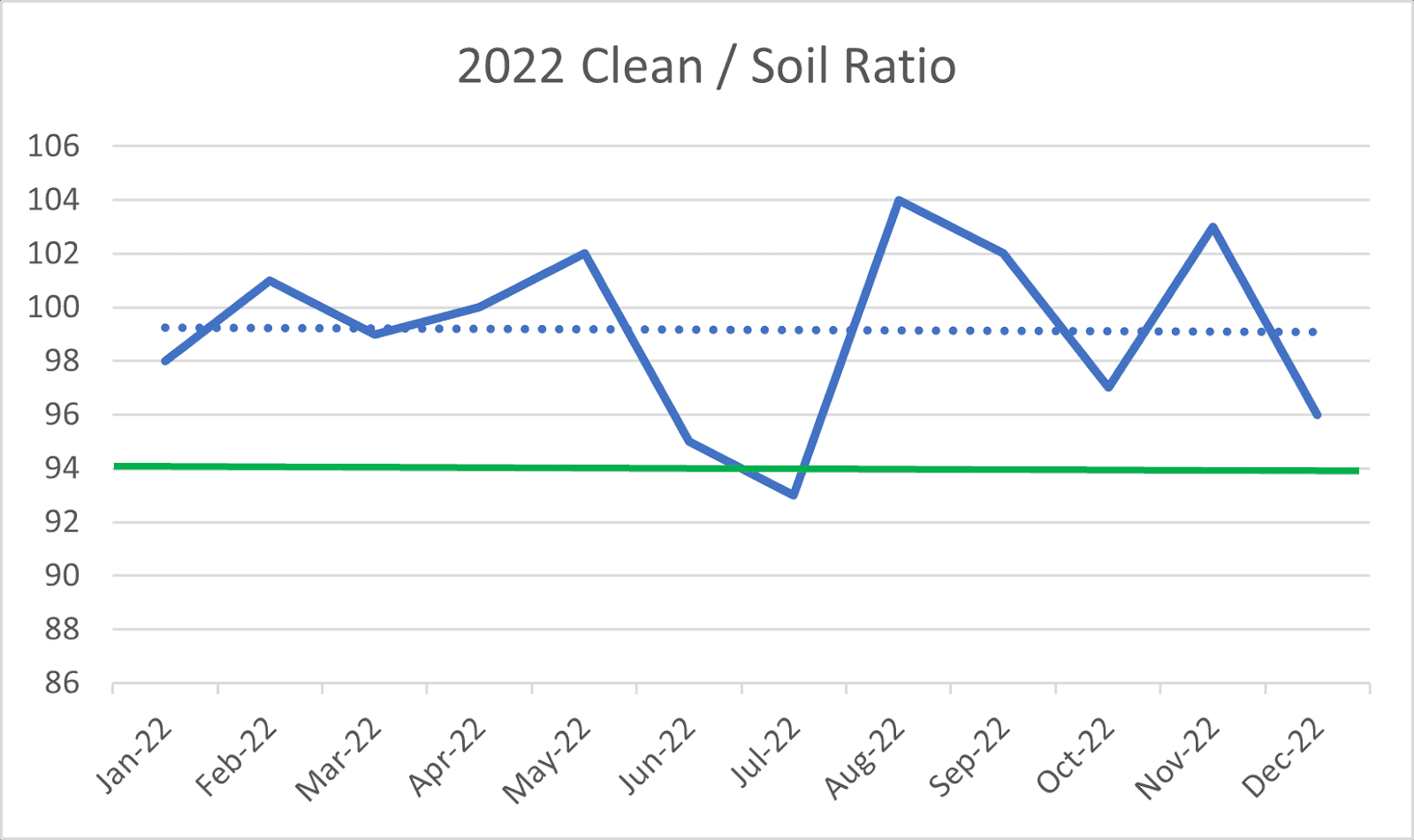

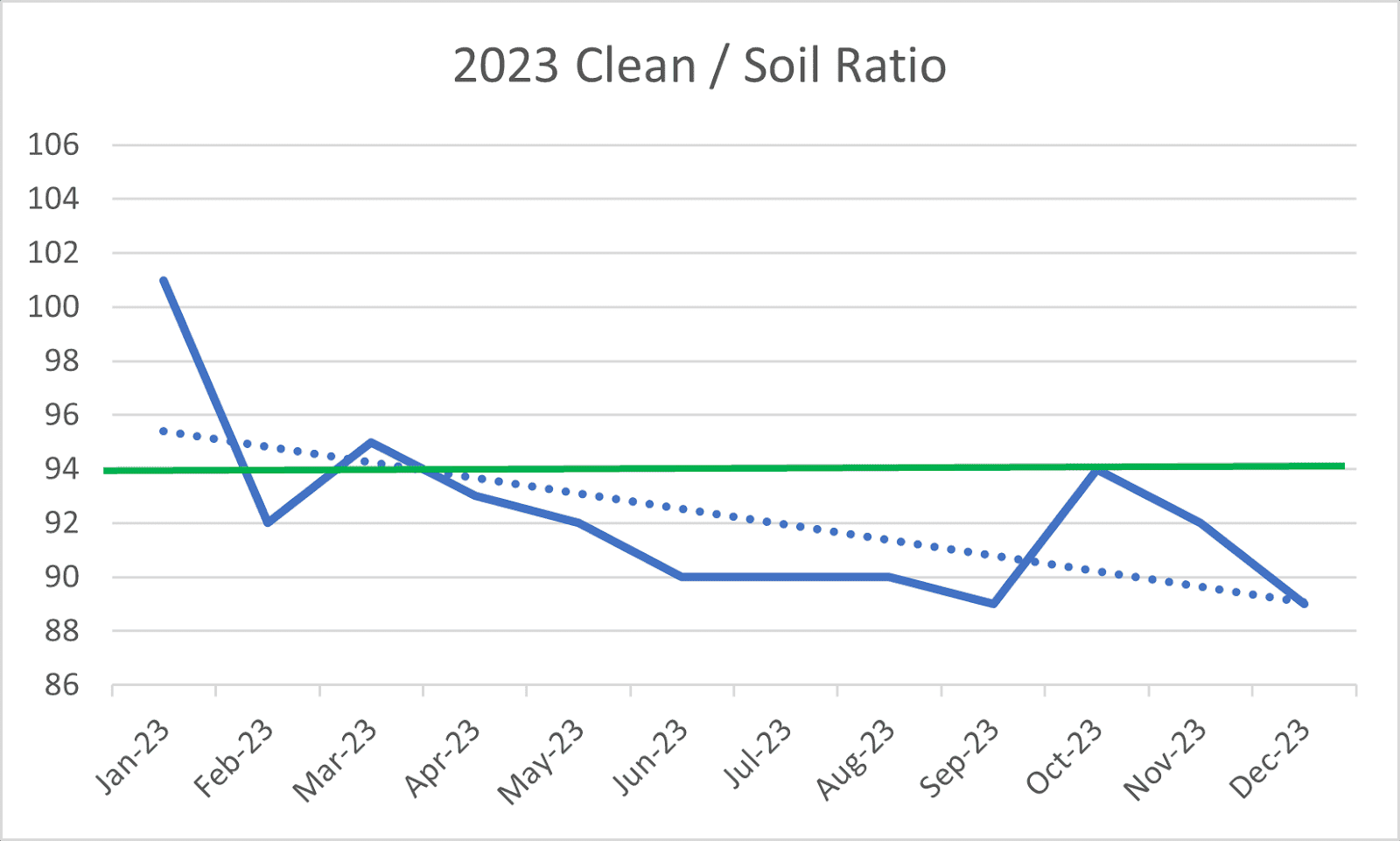

Let’s compare Shady Grove Medical Center’s 2022 and 2023 data. The clean / soil ratio should be 94% or lower as indicated by the green line. You can see in 2022, the blue dotted clean / soil ratio trendline plateaued and in 2023, it shows a sharp decline. Their overall linen costs in 2023 had a decrease of nearly 9% due to the reduction in linen loss charges. That is something to celebrate!

How to start

Shady Grove’s first action was to ensure smooth processes for the EVS team. EVS leaders wanted to fix what they could control directly so they focused on instilling good ordering habits. Additionally, they worked diligently to collect all soiled linen to send back to HandCraft. From previous experience, Greg knew it was possible to get a gross weight of 560 lbs. per soil cart if you stack the soil bags correctly, so he trained the team to this standard. This ensures more soiled linen bags go back to the plant at each pick-up.

Once comfortable with how the linen room was running, the EVS team moved on to address linen usage in the hospital departments by adjusting the periodic automatic replenishment (PAR) levels. EVS leaders reviewed census data for the current and past year as well as talked to each department to understand how much linen was used per patient. From there, the EVS team set PARs for each delivery location based on census and linen use per patient with a small buffer, significantly reducing the amount of linen stored in the departments.

To get buy-in from nursing, EVS leaders provided data that supported the PAR levels and explained how to access additional linen in the linen room. They emphasized that linen in each department was for day-to-day operations and the extra linen for extraordinary circumstances was available in the linen room. At first, many departments called saying they were out of or low on linen. EVS leaders addressed each of these calls one-on-one with the department. This hands-on and personal approach helped the nursing staff to quickly build confidence in the linen process, reducing unnecessary calls.

The next and more difficult step was educating the clinical staff. Changing culture is always challenging. The EVS team worked through Shady Grove’s clinical educator to communicate best practices for linen usage, including:

- placing unusable linen in purple bags, and how the hospital gets credits from this program

- not putting linen in the trash or in red bags

- linen conservation principles.

Knowing people tend to go back to previous habits if there is no follow-up, ongoing reinforcement was also part of the education plan.

How to continue

The hospital’s unit managers currently perform linen rounds weekly to monitor behaviors. EVS team members join these rounds to ensure proper linen management. At times while rounding, the team catches issues like linen stored in cabinets or closets. The rounds provide an opportunity to address the issue on site and do just-in-time teaching to remind staff about the PAR levels and other quick linen management tips.

The Shady Grove team has a list of next steps to tackle as well, such as working with EMS to ensure there is a 1:1 exchange of linen. Greg admits the work is relentless. The moment you take your eye off the ball is the month when your clean / soil ratio will increase. There is not one thing that will fix the issue. A plan with a stair-step methodology can help determine what is making a difference.

This approach can work at other facilities but the steps may be different. Every hospital is unique in its culture and processes. It could take one experienced person spearheading the initiative or a project management team making decisions. For Shady Grove, providing the actual cost of linen loss to the directors worked for Greg. This “sticker shock” can be all that it takes to get the approval to bring linen management under control.

We want to thank Greg Hebron and Adventist HealthCare Shady Grove Medical Center for sharing their success story with us.

Contact HandCraft for more information

If you are looking for the right team to help prevent linen loss and decrease your linen loss costs, you found us. We have the experience, the industry-backed expertise, the technology and the professionals to help you achieve your goals. Remember to look at our Linen Awareness Program – healthcare linen management strategies that save costs and improve service.

Call us today at (888) 358-8671 or reach us here for more information on our services.

About the Author

Dyan Troxel, MSN, RN

Dyan is a registered nurse with experience in several clinical and non-clinical settings including Surgical ICU, Neonatal ICU, Education, Process Improvement, and Healthcare Leadership.