Come Tour Our Healthcare Linen Plants

April’s blog was about HandCraft’s service team coming to your facility. We would like to extend the offer for you to come to our facility and see us in action. Our tunnel washers and chemistry farm are part of the process that keeps your patient linen hygienically clean. Let us walk you through our procedures with an infection prevention viewpoint.

At HandCraft Linen Services, we take our role in infection prevention seriously. Employees receive new hire and annual training related to infection control procedures and bloodborne pathogens. HandCraft also offers the Hepatitis B vaccination series for employees in certain roles.

The Soil Side

In delivery trucks, we separate clean linen from soiled linen by plastic covering the linen in the carts. Drivers sanitize cargo areas of trucks using an electric fogger with an EPA-registered sanitizer a minimum of once a week. Emptied soil carts go through an automated cart wash using EPA-registered disinfectants.

All soiled linen is considered hazardous and is handled using standard precautions. Plant workers wear PPE (gloves, gowns, face masks, eye protection, hair covers) as appropriate for their work area.

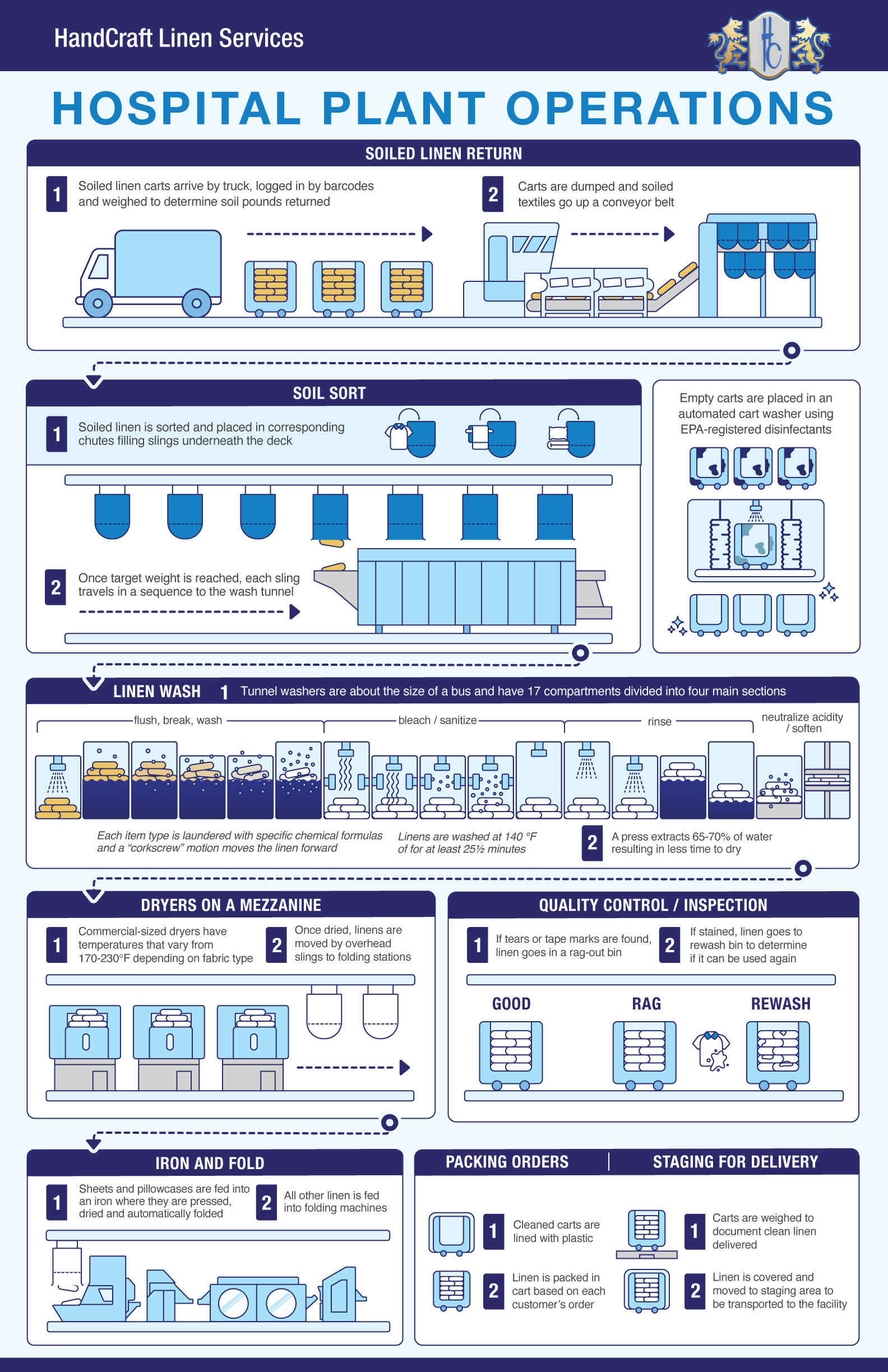

The soiled linen goes through a wash cycle with four features to ensure we provide hygienically clean linen.

- Mechanical: Each tunnel washer has seventeen compartments and uses a “corkscrew” motion to continuously move the linen forward.

- Chemical: Computerized programs track what items are in each compartment of the tunnel dictating corresponding wash chemistry that our chemical company prescribes. Our chemicals meet CDC guidelines for healthcare laundry and are 99.9% effective at reducing pathogens known to cause hospital-acquired infections. We monitor our chemistry several times a day with the goal of having a skin-neutral pH.

- Thermal: Linens are washed at a minimum temperature of 140 degrees.

- Interval: The full wash cycles last at least 25 ½ minutes.

A press extracts 65 – 70% of water resulting in less time to dry.

The Clean Side

There is physical separation between the clean and soil areas by walls and doors with negative airflow in the soiled linen area. Employees remove their PPE before entering a decontamination room anytime they transition from the soiled side to clean side of the plant. Employees wash their hands in the decontamination room.

Dryer temperatures vary from 170 to 230 degrees Fahrenheit depending on fabric type. The drying process minimizes microbial growth after washing. Sheets and pillowcases are fed into an iron where they are pressed, dried, and automatically folded. All other linen is fed into folding machines. And we use antimicrobial floor mats at drying and folding machines to prevent contamination.

Before their next use, we line bulk carts with clean plastic and pack clean linen based on customer orders. Once completed, the linen is covered, and carts are moved to a staging area to be transported to the facility.

Additionally, HandCraft has procedures to provide a hygienic environment for processing healthcare linen. We blow down the equipment daily to remove lint. Lint is also blown down from light fixtures, pipes, and fans. Floors are damp mopped with an EPA registered disinfectant.

We take pride in achieving TRSA’s Hygienically clean certification but that is not why we do what we do. We are YOUR partner in providing quality products and services that contribute to the health and wellness of every patient.

Below, you can view an infographic showing HandCraft’s Hospital Plant Operations

Contact HandCraft for more information

If you are looking for the right team to help prevent linen loss and decrease your linen loss costs, you found us. We have the experience, the industry-backed expertise, the technology, and the professionals to help you achieve your goals. Remember to look at our Linen Awareness Program – healthcare linen management strategies that save costs and improve service.

Call us today at (888) 358-8671 or reach us here for more information on our services.

About the Author

Dyan Troxel, MSN, RN

Dyan is a registered nurse with experience in several clinical and non-clinical settings including Surgical ICU, Neonatal ICU, Education, Process Improvement, and Healthcare Leadership.